Detection Solution

WE LEAD THE FUTURE THROUGH CHALLENGES !

Logistics monitoring

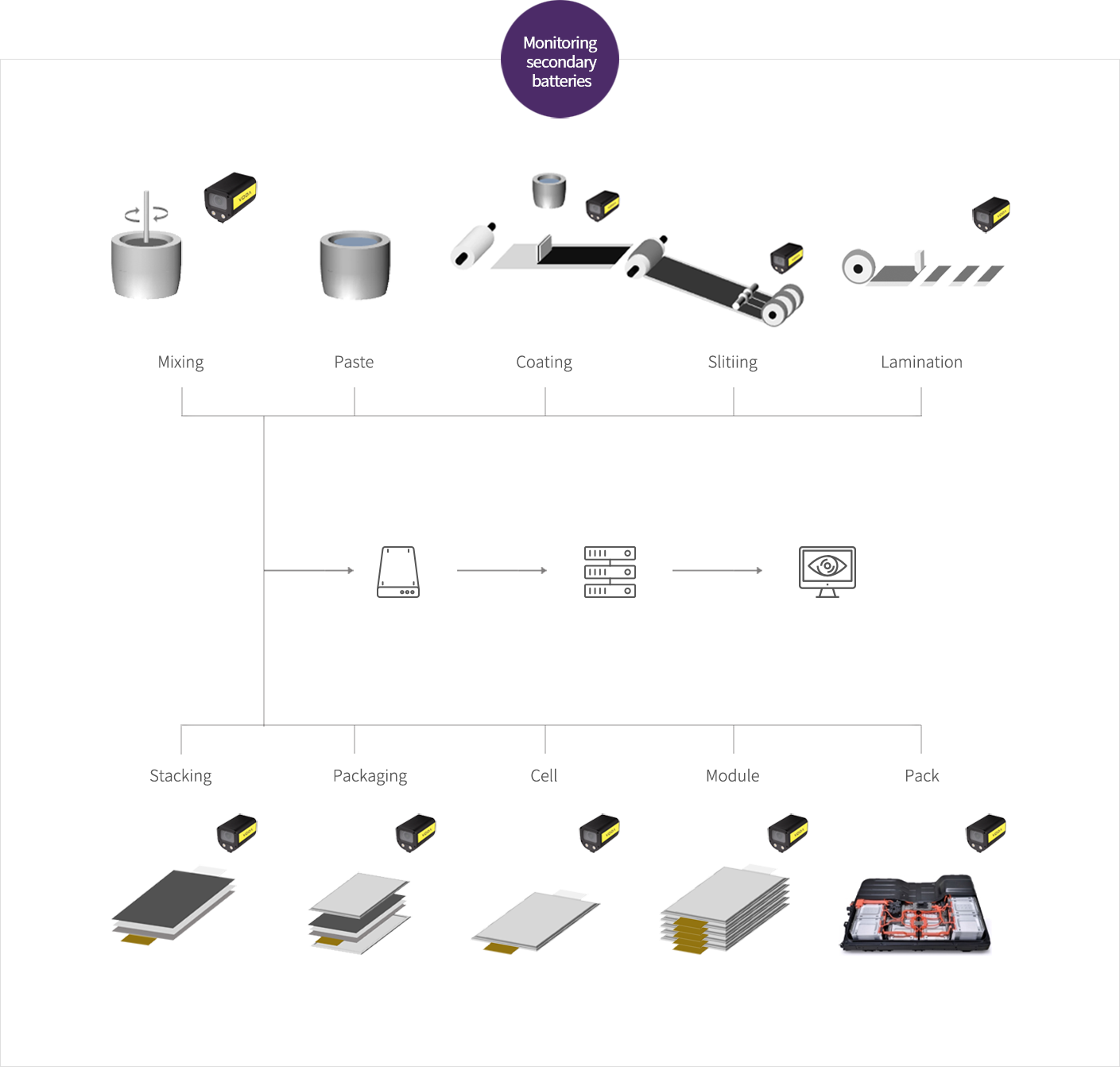

Rotating machine monitoring

Process monitoring

- Detection of abnormal behavior in repeated movements

- Detection of abnormal behavior during product delivery

- Detection of a missing product

- Product appearance test

- Detection of a missing part

- Detection of inclusion of a different product

- Anomaly detection by area

- Movement detection

- Equipment error detection

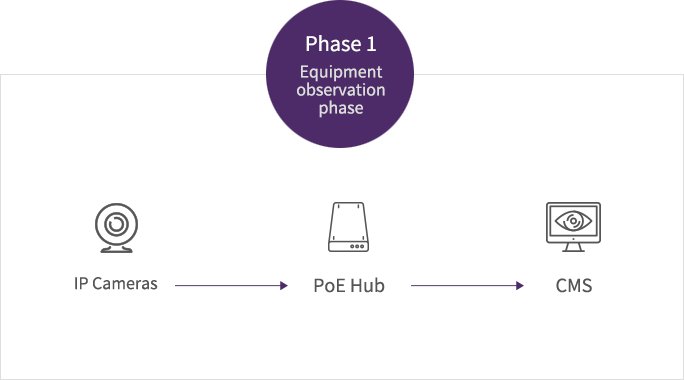

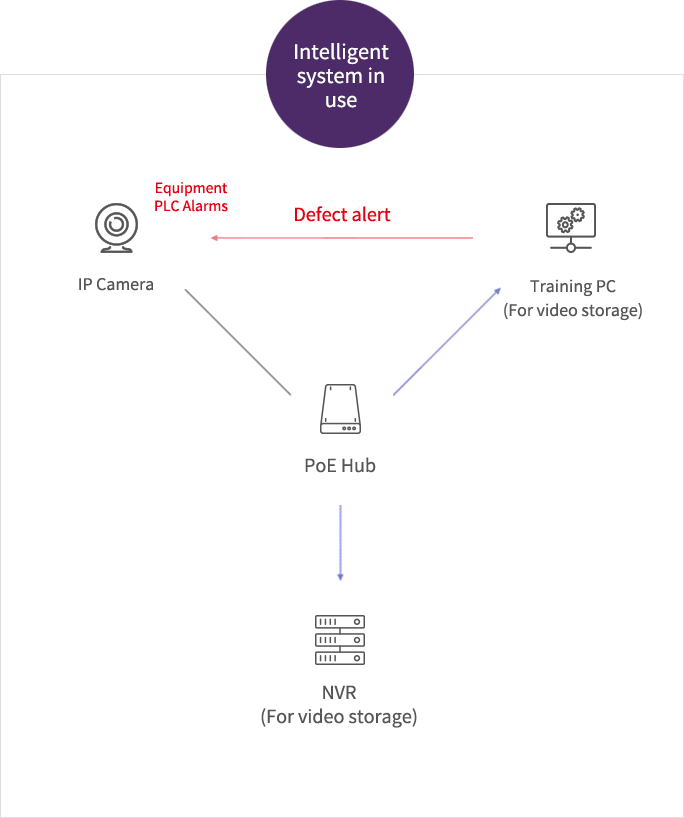

- Great for equipment running 24/7

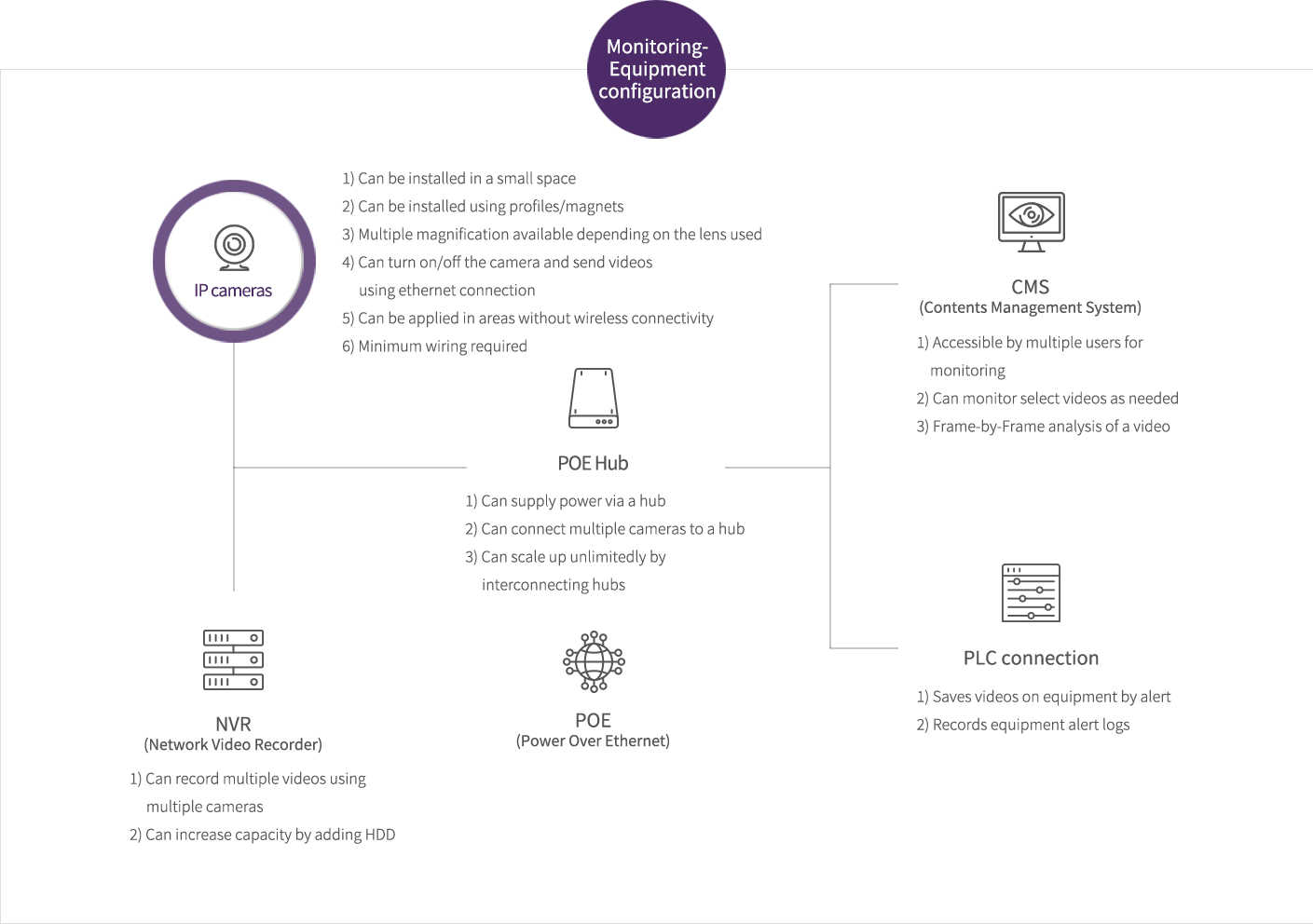

- Records equipment 24/7

- Uses a high-capacity NVR

- Basic equipment from L and G brands used

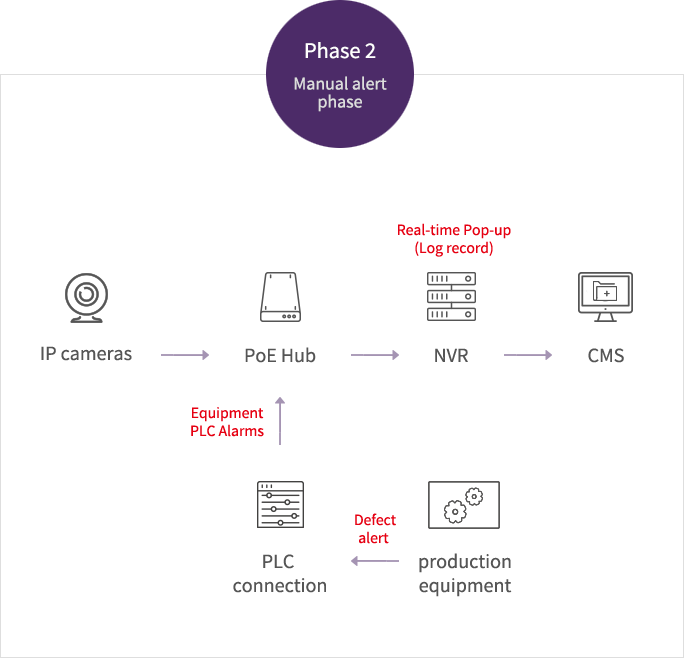

- Connection to the equipment’s PLC signals

- Records videos before and after the PLC alert is sounded

- Easy to analyze the timing of the abnormal behavior

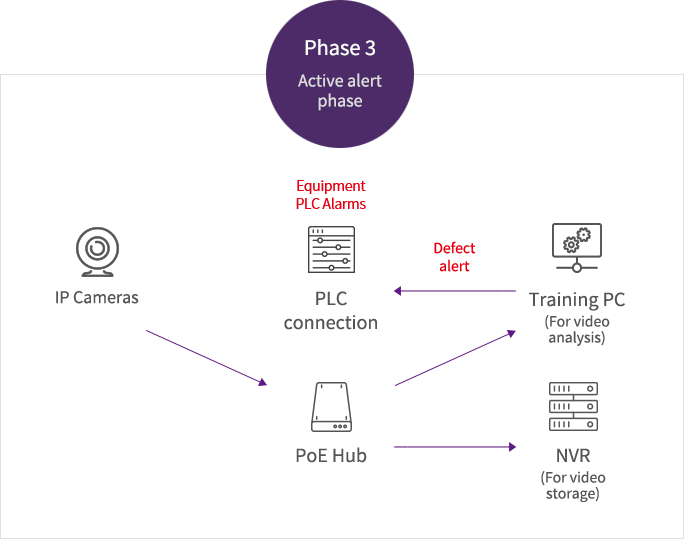

- Connection to AI-powered intelligent PCs

- Anomaly detection applied

- Enhanced equipment failure detection

※ Note : Images may be blurred for security reasons.

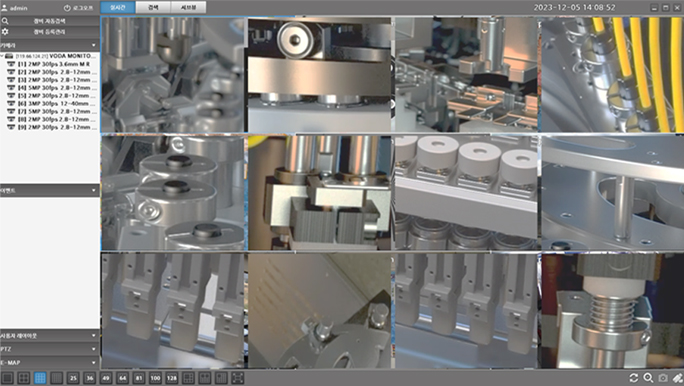

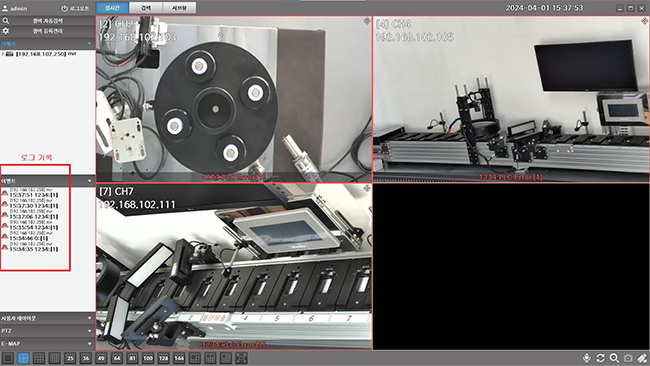

Screenshots of the monitoring system

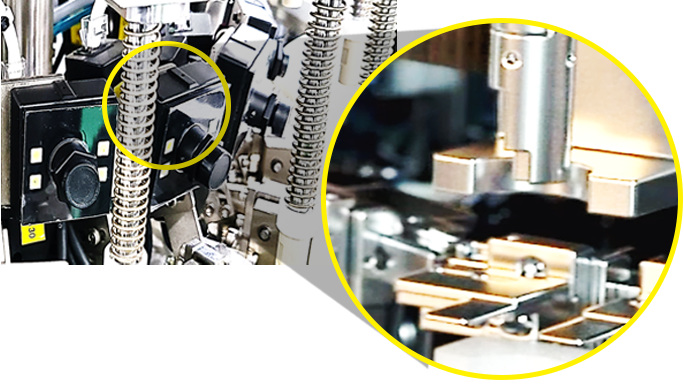

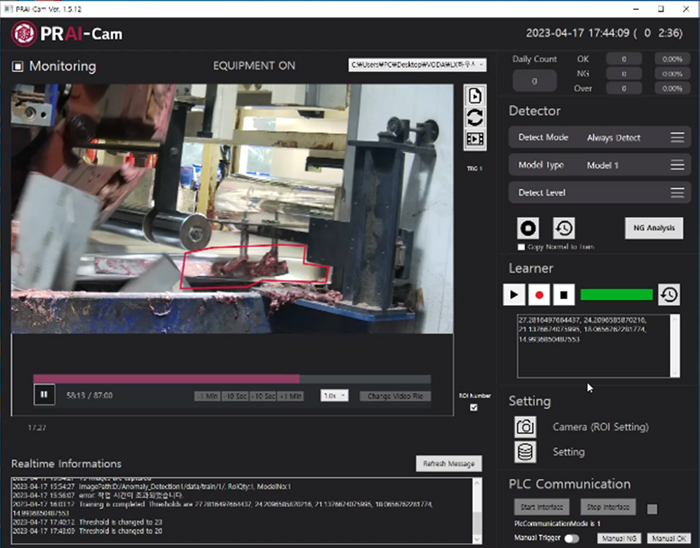

Deployment example 1 – Zooming in on process details, small sections, or dangerous processes

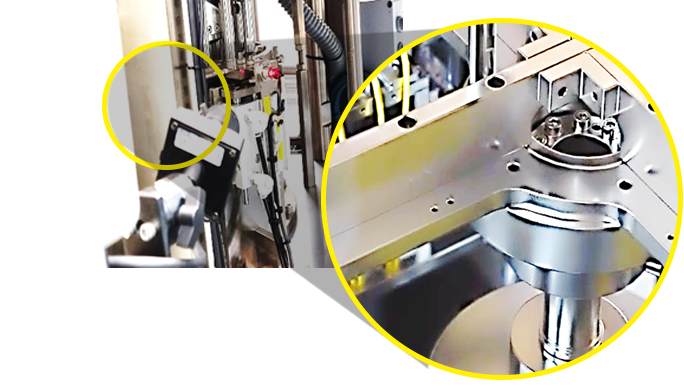

Deployment example 2 – Zooming in on process details, small sections, or dangerous processes

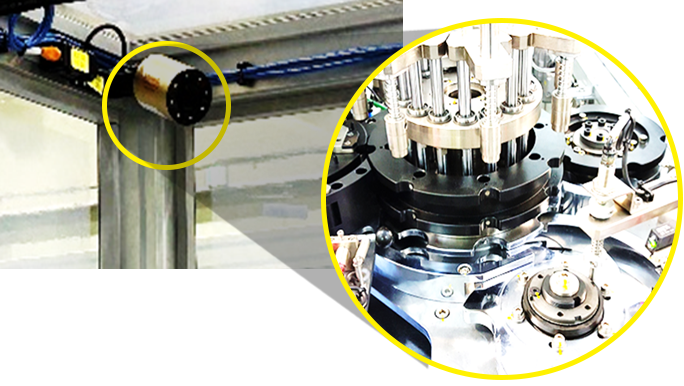

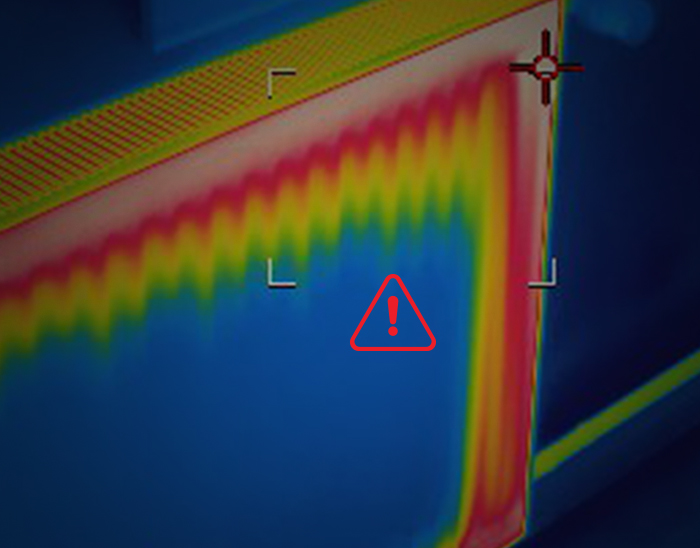

Deployment example 3 – Better understanding of process flows

Deployment example 3 – Processes taking place in a dark place or dark rooms

System screen examples – From YouTube

PLC system screen examples – A pop-up window appears after arbitrarily applying three PLC errors while viewing a split screen

Failure, breakdown,

damage

Missing parts, inclusion of a different product, distortion, foreign matter, damage, printing errors

Entry of workers into

a safe area & Fire

Automated aggregation of

product performance

Primary uses

- Our systems monitor and automatically adjust different parts of a manufacturing process, including product alignment, the sequence, and the assembly path to ensure the highest product quality.

- Monitors the state of equipment installed and jamming, decoupling, and coupling of machines to fundamentally prevent accidents.

- Supports location recognition and tracking of product transfer machines in the manufacturing process, and immediately responds to equipment collisions.

※ Monitoring of production progress

VODA’s intelligent systems help you monitor the manufacturing process and the production progress of a product in real time, so you can achieve process optimization.

※ Monitoring of the state of equipment, product location, and damages

Our systems monitor the production equipment in real time to prevent accidents and set up an operation system capable of responding to accidents immediately.

Other uses

- Product specification inspection for the appearance, colors and other flaws in the end product.

- Product inspection in terms of the welding quality, dents, the state of fastened areas, and other conditions.

- Prevents occupational and environmental accidents by monitoring leakage of hazardous substances.

- 24/7 monitoring of industrial premises, including restricted areas, electrical rooms, and hazardous material storage.

※ Quality inspections

VODA’s intelligent systems help you analyze videos when checking the product appearance and colors, so you can better manage product quality.

※ Hazardous materials management

Helps you monitor hazardous materials, dangerous gas, sewer and wastewater leakage in real time and respond quickly when identifying signs of relevant problems.

※ Intrusion and fire detection

We create a system that monitors important areas in the premises and detects abnormal behavior including the presence of an intruder and fire, so you can respond immediately.

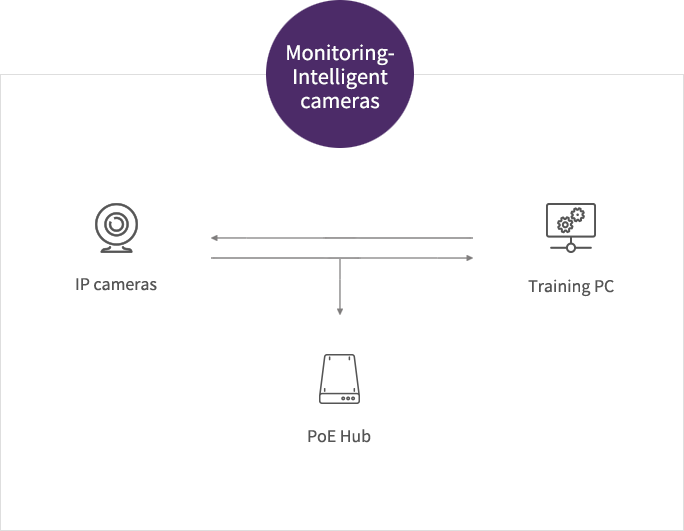

Deep learning system deployment

It utilizes deep learning to increase customer confidencein claim prevention and product quality by improving inspection recognition

in existing inspection systems and various environments where screening is weak.

Collection of

normal and

faulty images

Classification

of recognition

errors

Training

and tuning

AI models

Strengthening the

flaw recognition

capacity

Bumpy surface

Round bottles

Reflective surface

Presence inspection - Detects the presence of a product in the target location

Presence inspection - Detects minor flaws in the target location.

High-speed inspection - Detects flaws in the target moving at high-speed.

Address : 689, Jeongjung-ri, Osong-eup, Heungdeok-gu, Cheongju-si, Chungcheongbuk-do, Republic of Koreaㅣ

Working hours : Monday to Friday, 09:00 to 18:00 (Closed on Saturdays, Sundays, and public holidays)ㅣ Tel : +82-70-4647-0408

Fax : +82-70-8230-0408 ㅣE-mail : voda@vodai.co.kr

Copyright © Voda Co., Ltd. Inc.All Rights Reserved.